Production Process

We work shoulder to shoulder with our clients to ensure their products meet the requirements and design specifications they are after. Our expert team have a depth of knowledge about the manufacturing process that ensures we exceed your expectations on every job.

Step 1

Raw Material

Our in-house testing and analysis of materials include inspection of our raw brass’s characteristics and chemical composition. Sourced from only certified manufacturers, we also identify and codify the raw material and guarantee total traceability throughout the entire production cycle.

Step 2

Design & 3D

Modeling

Our technical office works closely with our clients through the research and development stages. Product optimization, prototypes, and simulation software help reduce costs while maintaining exceptionally high production standards.

Step 3

Dies & Tooling

We produce dies and tools that speed up the manufacturing process to minimise wait times. Collaboration with our hot forging department allows for constant verification of the product and added quality checks that improve and accelerate the production process.

Step 4

Hot Forging

Every product is the result of decades of knowledge surrounding the best practices in hot forging. Highly efficient machinery makes fast work of the hot forging process. Our brass billets are heated up and hot forged to produce a raw product ready for trimming and surface treatments.

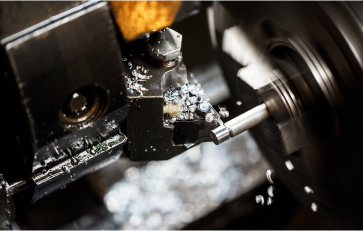

Step 5

Machining

We use state of the art machinery that allows for high production flexibility and large and small runs. Our investment in our technology makes machining products for a wide range of customer requests possible, no matter how they need to be customised.

Step 6

Assembly and Testing

We are dedicated to product control, testing and monitoring at every stage of the production and assembly process. From the in-house analysis of raw material to testing prototypes, we test and evaluate for any problems or defects to the highest level.

Step 7

Packings

We can assemble, pack and deliver your products at a competitive speed compared to imported products and will talk you through your packaging options.

Other Services

Get Started With A Free Consultation

If you have a product, or component idea and don’t know where to start, talk to us. Our engineering and manufacturing experts will talk through your requirements, specifications and budget and provide the best solution for your requirements, free of charge.

As industry experts our shop has decades of experience bringing innovative and functional plumbing solutions to life.

Forge ahead with the experts in plumbing solutions

Have a product or component project you want to get started with? We can arrange a free quote or consultation with our engineering and manufacturing experts to talk through your requirements.